Low Pressure/Vacuum (LPV) Tube with Controlled Length for Automatic Sampler

Try our family of novel low pressure/vacuum tubes for NMR and EPR experiments as an alternative to other similar tubes. A 4X larger sealing surface eliminates leaks and greatly increases its lifetime when compared to traditional gas-tight tubes. It continues to offer a convenient flame-free sealing solution for air sensitive or volatile liquid samples at any pressure from vacuum to pressure slightly above 1 bar.Featured highlights: Greaseless PTFE piston provides a 100% contamination-free seal.Axial symmetric design guarantees its application in spinning experiments.More economical to reduce experimental costsReliable - standard sizes can ship within 1-2 business days after receipt of order.Spare/replacement Pyrextube available*For custom lengths contact Customer Service.

Details

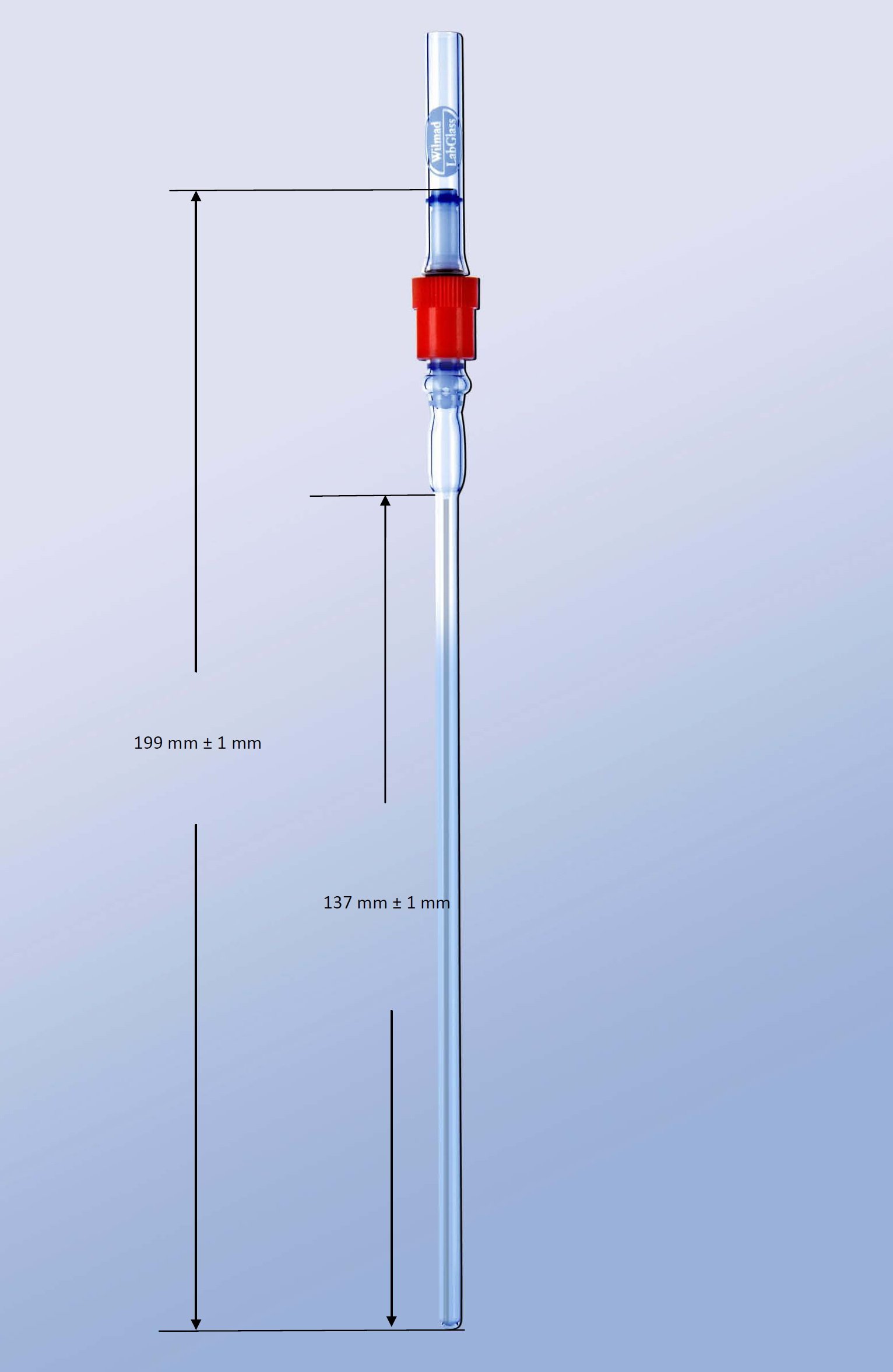

These LPV tubes are optimized for automatic samplers that require clearance on sample tube height. The length of this system after tightening the piston and removing the top glass vacuum adapter is 200 mm; the bottom NMR tube is 138 mm.

Specifications

- MHz Rating:600

- Camber/ Concentricity:13 / 6

- OAL / Tube Body* (mm):200/138

Application Notes

*LPV Tubes consist of 3 parts - 5 mm Pyrex® vacuum adapter, 5 mm PTFE vacuum lock valve and piston assembly and an NMR tube with the threaded glass section sealed on; also known as the spare tube.For Spare Tube orders the original LPV part number must be specified; i.e. 528-LPV-7 as "X" denotes the style (528) and length (7").Important Note:Product numbers that include "PQ" belong to our Precision Tube Family with an OD and ID tolerance of 0.013 mm. Those with "SQ" are not Precision and their OD and ID may vary as much as 0.4 mm. For EPR experiments that must estimate electron spin density and/or produce highly repeatable signal amplitude between different runs we strongly recommend our Precision EPR Tube. Due to the nature of glass, Extreme Caution should be exercised when using at elevated or reduced pressures since a tiny scratch on the glass surface would significantly lower the tensile strength. Adequate safety shielding should always be used when working in these conditions.